Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modell: 110-315mm

Marke: Huade

Anwendung: Bar, ROHR

Verarbeitung Von Kunststoff: SPORT, PP

Stand: Neu

Schraubendesign: Einzelschraube

Schraubenmaterial: 38CrMoALA

Schraubendurchmesser (mm): 75

Verhältnis Von Schraubenlänge Zu Durchmesser: 38: 1

Ausstellungsraum Standort (in Welchen Ländern Gibt Es Probenräume In Übersee): Ägypten, Deutschland, Philippinen, Saudi-Arabien, Mexiko, Russland

Herkunftsort: China

Garantiezeit: 1 Jahr

Kernverkaufsargument: Wettbewerbspreis

Out-of-Warranty-Service: Video technischer Support, Ersatzteile

Wo Können Lokale Dienstleistungen Anbieten (in Welchen Ländern Gibt Es In Übersee -Dienstleistungen Im Ausland): Ägypten, Philippinen, Mexiko, Russland, Spanien, Südkorea, Sri Lanka

Anwendbare Branche: Baustoffläden, Produktionsstätte, Reparatur von Maschinen, Energie & Bergbau

Marketingtyp: Neues Produkt 2020

Video Factory Inspection: Bereitgestellt

Mechanischer Testbericht: Bereitgestellt

Kernkomponenten -Garantiezeitraum: 1 Jahr

Kernkomponenten: Lager, Motor, Pumpe

Verpakung: Holzpalette

Produktivität: 600

Transport: Ocean

Ort Von Zukunft: CHINA

Unterstützung über: 10

Zertifikate : CE

HS-Code: 84778000

Hafen: Shanghai Port

Zahlungsart: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

110-315mm 3 layers HDPE water pipe extrusion line

110-315mm 3 layer HDPE tube production line / making machine

Diameter Range (mm): 110 140 160 180 200 225 250 315 wall thickness by request

Main Extruder Motor Power: 185kw

Line Space Occupation: 45mx5mx3m

Capacity: 500-600kg/h

Introduction of HDPE 315-630mm big size pipe production line

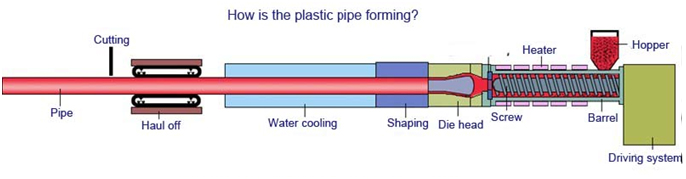

The unit consists of single screw extruder , die head, vacuum cooling tank, haul-off machine, planetary(swarf less/ chip free cutter / no dust cutter) cutting machine, winder stacker and so on.

Turn-key solution can be provided, like laser printer ,crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

Characteristics of PE 3 layers Pipe extrusion line

Process Flow for PE 630-1200mm pipe making machine :

Raw material+ master batches → Mixing → vacuum feeding → material dryness → single screw extruder → color string extruder → spiral mould → vacuum calibration tank → spray cooling water tank → spray-code printer → haul-off → no-dust cutter → Double disc Winding/ Stacker → finished product inspecting &packing

Model :SJ75/38 extruder of HDPE 110-315mm Pipe extrusion line

Diameter of screw: Φ 75mm

Length diameter ratio of screw: 38:1

Driving motor power: 160kW high speed screw

Die head and mould ( including the bush,pin and calibrator )

Materials: 40Cr Steel

Structure: Spiral or Basket

Single cavity design

3 layer design

Vacuum Calibration Tank

length: 9000mm

Tank materials: 4mm 304 SSMaterials

Double-chamber structure vacuum and cooling

Water temperature and level controlling technology

High pressure and stable water jet

Pressure protection design

4 caterpillar Haul-Off machine :

ABB Frequency motor driving

Upper and lower caterpillar is driven separately by the frequency inverter

Fast change type pads

High friction fact and anti-wear out silicon rubber Pads

Metering counter

Cutter:

Non-dust cutter, Blade rotates around pipe and cut off pipe with smooth surface.

Synchronous control

Cast aluminium fixture unit

High Quality Alloy Blades

Smooth Cutting surface

Servo motor Synchronous control

Stacker

Stainless steel 304 as touching material

Discharge driving by air cylinder

Produktgruppe : HDPE PP-Rohrextrusionslinie

Mobile Seite

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.